Flexible solar cells are finally here! This time it was developed by Chinese scientists. It is as thin as paper and can be folded thousands of times.

Prior to this, there was a famous loser in the field of thin film solar energy – Hanergy. In addition, Shangmai New Energy, invested by Dr. Shi Zhengrong, the godfather of China’s photovoltaic industry, has also been committed to research in this field.

At this year’s SNEC exhibition, Zeoluff also noticed that daycare photovoltaics had flexible lightweight module products displayed on site, which was quite amazing.

The current photovoltaic industry is somewhat restless, but in the field of photovoltaic scientific research, it is quite calm. There is definitely a long way to go from research achievements to industrialization, but we still need to praise young Chinese scientists!

Here comes the ultra-thin, flexible solar cell!

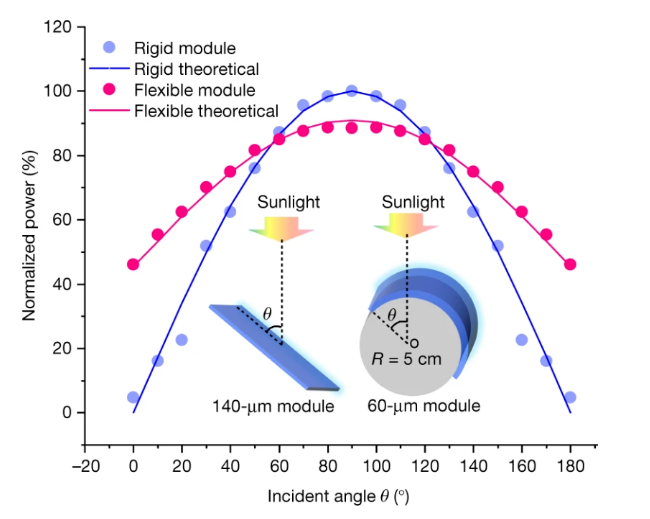

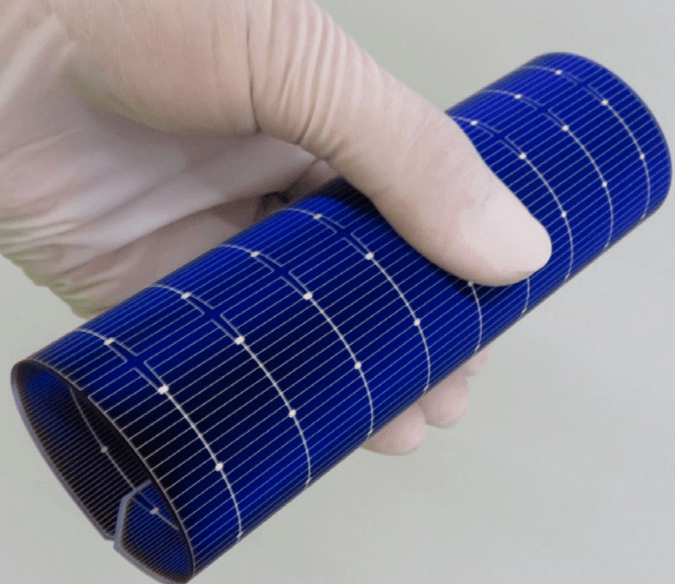

Chinese researchers have developed a smooth edge processing technology based on which flexible monocrystalline silicon solar cells are as thin as paper, with a thickness of 60 microns, and can be bent and folded like paper. The relevant research results were published online in the journal Nature on May 24th and were selected as cover articles.

Flexible monocrystalline silicon solar cell modules have been successfully applied in fields such as near space vehicles, photovoltaic building integration, and in vehicle photovoltaic systems.

Single crystal silicon solar cells are currently the fastest developing type of solar cells, with the advantages of long service life, complete preparation process, and high conversion efficiency. They are the leading products in the photovoltaic market.

At present, monocrystalline silicon solar cells are mainly used in distributed photovoltaic power plants and ground photovoltaic power plants. If they are made into flexible solar cells that can be bent, they can be widely used in buildings, backpacks, tents, cars, sailboats, and even airplanes, providing lightweight and clean energy for houses, various portable electronic and communication devices, transportation vehicles, and so on.

Liu Zhengxin, co corresponding author of the paper and researcher of Shanghai Institute of Microsystems, Chinese Academy of Sciences, said that since monocrystalline silicon is a high-purity silicon material with very high crystallinity and high hardness, it is difficult to make flexible solar cells.

Silicon wafers are brittle materials that are easily broken. People tear a piece of paper or break something, usually starting from the edge, and the same goes for solar cells. Because when making solar cells, the surface is treated to create a bumpy structure that can better absorb sunlight, commonly known as a “pyramid structure”.

This time, the research team found the key to solving the puzzle.

They observed through high-speed cameras that the fracture of monocrystalline silicon solar cells during bending always starts from the “V” shaped groove at the edge of the monocrystalline silicon wafer, which is also defined as the “mechanical short plate” of the silicon wafer.

After making this discovery, researchers developed corresponding edge smoothing techniques, which involve treating sharp “V” shaped grooves into smooth ones and grinding them into “U” shapes. Technically speaking, this is called “symmetry processing of mesoscopic structures”, so that they are not easily broken after processing.

The journal Nature stated that Liu Wenzhu and Liu Zhengxin’s research “changed the rules”.

The paper points out that this edge passivation technology can achieve large-scale (>240 cm) commercial production, efficient (>24%) silicon solar cells, and can be rolled up like a piece of paper.

After about 1000 bending cycles, the battery can still maintain 100% power conversion efficiency. After being assembled into large (>10000 cm2) flexible modules, these batteries still retain 99.62% power after 120 hours of thermal cycling between -70 ° C and 85 ° C. In addition, when connected to soft airbags, they still retain 96.03% of power after 20 minutes of exposure to the airflow – soft airbags simulate the wind in a storm.

Prior to this, thin film solar cells made of amorphous silicon, Cu (In, Ga) Se2, CdTe, organic compounds, and perovskite achieved flexibility, but their use was limited due to their low power conversion efficiency. Moreover, taking perovskite batteries as an example, toxic substances are released into the environment, and their performance is poor under large areas and unstable operating conditions.